Projects

Pneumatic Fender Installation Project

April 2021

The pneumatic fenders of FSRU JAWA SATU were lifted from the deck and installed alongside the portside of the FSRU. Five pneumatic fenders and two baby fenders were installed on the freeboard portside using the 15 MT pedestal crane of FSRU JAWA SATU. This project was supported by our 4000 HP OSV and involved experienced engineers, marine teams, and offshore riggers.

September 2021

In September 2021, the fender connections were replaced with a brand new system and strengthened with additional parts. The repair was conducted using the floating method in a clear area near the Cilamaya anchorage area, West Java. This project was supported by a 5150 HP AHTS and involved experienced engineers, marine teams, and offshore riggers.

Sea Water Lifting Pump (SWLP) Project

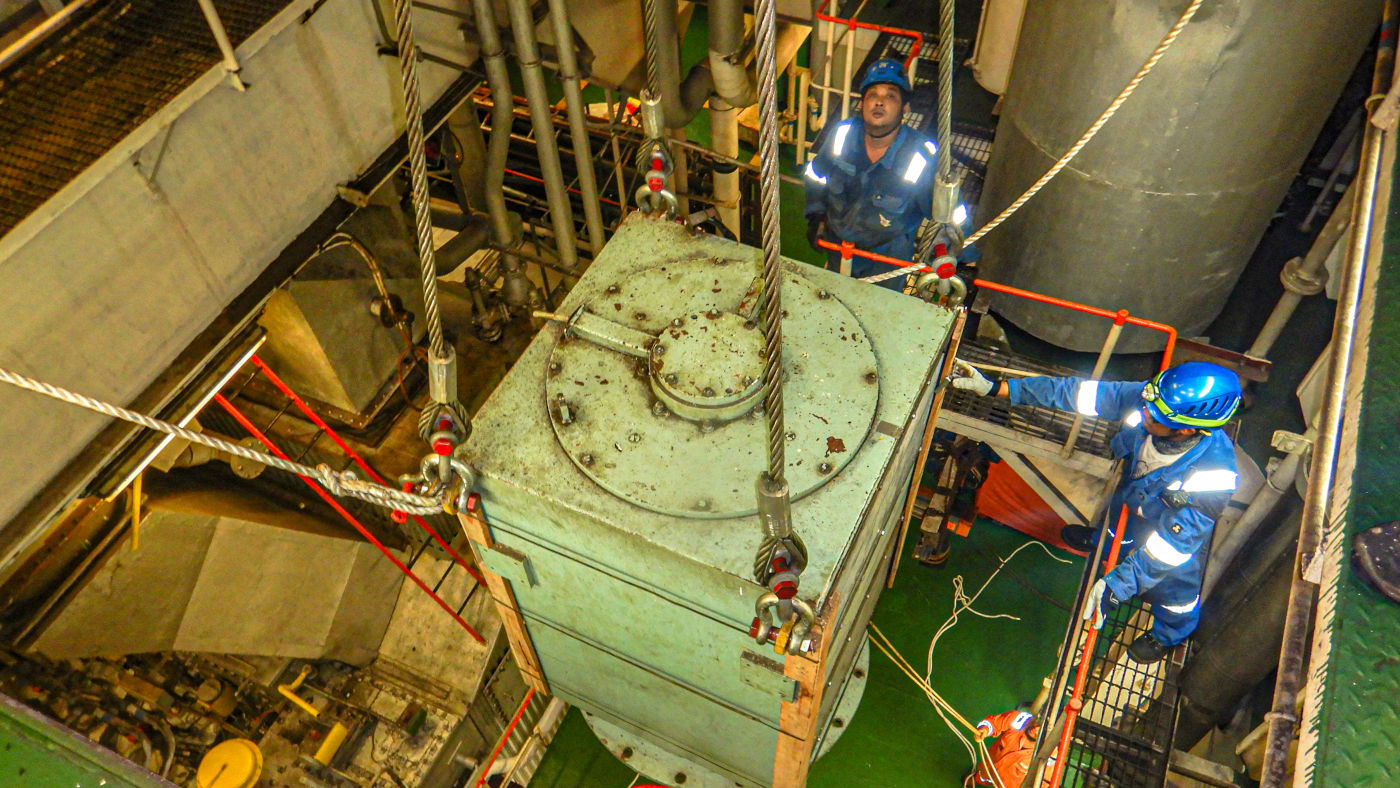

The 7 MT sea water pump motor was lifted out from engine room of FSRU Jawa Barat and temporarily stored to the deck of the Accommodation Work Barge. It was lifted out using her 47 meters length boom crane.

The project was categorized as a critical lifting because the sea water pump which was sheathed on 2 meters offset the center line of the engine sky lite. The lifting process became more difficult because of the extreme narrow access through the engine sky lite.

Subsea / Underwater Survey

Our supply vessel was entrusted by PT EGS Marine to support their geophysical subsea project, which ran from July 2021 to December 2021. The project was completed successfully.

Pre-lay Grapnel Run (PLGR) Project

Our supply vessel was engaged by PT EGS Marine to support their geophysical subsea project from July 2021 to December 2021, specifically for the Pre-Lay Grapnel Run (PLGR). The project was successfully completed.

Project Summary

PT. EGS Indonesia

July - Dec 2021

Subsea geophysical Survey

PT. Jawa Satu Power

Jan - Sept 2021

- Pneumatic Fender installation of FSU JAWA SATU

- Boarding platform installation

- Pneumatic Fender disconnection, repairment & reconnection

- Conducted pneumatic ender survey condition

PT. Humolco LNG Indonesia

Apr - June 2021

Temporary power supply for LNG Aquarius

PT. Elnusa Trans Samudera

Oct - Present 2021

Subsesa survey 2D seismic and Processing Data

PT. Perusahaan Pelayaran Equinox

Nov 2021

7 Te SWLP motor pump lifted offloading

PT. ANTAM Tbk

Nov 2021

Coal loading and transportation

Award

Indonesian Force Army (TNI AD)

Oct - Present 2021

Missile launch loading and transportation

Indonesian Force Army (TNI AD)

Oct - Present 2021

Missile launch loading and transportation

| Month | Client | Project |

|---|---|---|

| July - Dec 2021 | PT. EGS Indonesia | Subsea geophysical Survey |

| Jan - Sept 2021 | PT. Jawa Satu Power |

- Pneumatic Fender installation of FSU JAWA SATU - Boarding platform installation - Pneumatic Fender disconnection, repairment & reconnection - Conducted pneumatic ender survey condition |

| Apr - June 2021 | PT. Humolco LNG Indonesia | Temporary power supply for LNG Aquarius |

| Oct - Present 2021 | PT. Elnusa Trans Samudera | Subsesa survey 2D seismic and Processing Data |

| Nov 2021 | PT. Perusahaan Pelayaran Equinox | 7 Te SWLP motor pump lifted offloading |

| PT. ANTAM Tbk | Coal loading and transportation | |

| Indonesian Force Army (TNI AD) | Missile launch loading and transportation |

PNEUMATIC FENDER INSTALLATION PROJECT

Pneumatic Fender of FSRU JAWA SATU are hoisted from the deck into the sea, and installed alongside the FSRU JAWA SATU Portside. There were 5 (five) of Pneumatic fenders installed and 2 (two) baby fender hung on the free board portside of FSRU JAWA SATU.

The Pneumatic Fenders were lifted by 15 MT of FSRU JAWA SATU pedestal crane. The project was supported by of 4000 HP of our OSV and involving experienced engineer. marine team and offshore riggers.

PNEUMATIC FENDER DISCONNECT & CONNECTION PROJECT

Pneumatic fenders of FSRU JAWA SATU was found damage on the connection. The connection was replaced with a brand new and strengthened with additional part system. The repairment was done with the floating method at the clear area located near Cilamaya anchorage area, West Java.

The project was supported by 5150 HP of AHTS, and involving experienced engineer. marine team and offshore riggers.

FSRU JAWA SATU

Pneumatic Fender Installation Project

Pneumatic Fender of FSRU JAWA SATU was lifted offloading from deck to the seawater, and installed alongside of FSRU JAWA SATU Portside. There were 5 (five) of Pneumatic fenders was installed and 2 (two) baby fender hung on the free board portside of FSRU JAWA SATU.

The Pneumatic Fenders was lifted by 15 tonne of FSRU JAWA SATU pedestal crane. The project supported by 4000 HP of AHTS and involved by the experienced engineer, marine team, and the offshore.

Pneumatic Fender Disconnect & Connection Project

Pneumatic fenders of FSRU JAWA SATU was found damage on the connection. The connection was replaced with a brand new and strengthened with additional part system. The repairment was done with the floating method at the clear area located on near of cilamaya anchorage area, west java.

The project was carried out safely and support by 5150 HP AHTS (Anchor Handling Tug and Supply) vessel, and involving by the experienced offshore team consist of marine and naval engineer, master marine, and the riggers.

FSRU JAWA BARAT

Lifting Unloading SWLP Motor

The 7 tonne of SWLP motor of FSRU Jawa Barat was planned to be repaired onshore in the vendor’s workshop.

The Lifted offloading project has been carried out by one set of Crane Barge that have a 47 meters boom length as minimum criteria to reach out the SWLP Motor center line location in the FSRU Engine Room, and the AHTS vessel who act as towing barge and the anchor handling job vessel.

The lifted offloading of the SWLP motor is one of the critical lifting, due to its located in the narrow space and about 15 meter depth sitting in the engine room.

The crane barge was positioned herself to the nearest distance crossed to the FSRU which it’s about 2 meters distance, and the clashing distance between crane boom to the structure was only 1.5 meter distance.

The project was succesly done with safely. It was involved by the experienced mooring master captain, lifting specialist, field engi neer and the rigger team team.

LNG Aquarius

Providing temporary power to LNG AQUARIUS via generator. The generator was transported by our vessel to the LNG berthed Location, Kepulauan Seribu.